| Поиск по каталогу |

|

(строгое соответствие)

|

- Профессиональная

- Научно-популярная

- Художественная

- Публицистика

- Детская

- Искусство

- Хобби, семья, дом

- Спорт

- Путеводители

- Блокноты, тетради, открытки

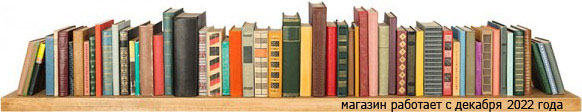

Friction Stir Welding of Aluminum Alloy and Development of ANN Model.

В наличии

| Местонахождение: Алматы | Состояние экземпляра: новый |

Бумажная

версия

версия

Автор: Saumil Joshi,Sheshang Degadwala and Dhairya Vyas

ISBN: 9786138964933

Год издания: 1905

Формат книги: 60×90/16 (145×215 мм)

Количество страниц: 264

Издательство: Scholars' Press

Цена: 57075 тг

Положить в корзину

| Способы доставки в город Алматы * комплектация (срок до отгрузки) не более 2 рабочих дней |

| Самовывоз из города Алматы (пункты самовывоза партнёра CDEK) |

| Курьерская доставка CDEK из города Москва |

| Доставка Почтой России из города Москва |

Аннотация: Now-a-days industries are concentrating on those metals, who has higher strength to weight ratio. Thus, many industries such as aviation factories, marine industries, auto industries, packaging industries, etc. are replacing steel structure into aluminum alloy structure. Aluminum alloy has good strength in respect to weight compare to steel. In addition, aluminum alloy possesses outstanding properties such as good corrosion resistance, good conductivity of electricity and heat, good reflectivity of light, non-toxic alloy, recyclable, etc. During the application of aluminum alloys in industries, there is need to join them through welding. But the welding of aluminum alloy is very difficult through conventional welding techniques. It faces so many problems such as cracks, formation of oxide at weld region, reduce strength of joint, large HAZ area, incomplete penetration, solid inclusion, spatters, etc. Other joining processes like joining through nut & bolt, snap joint, mechanical riveting increase the weight of product, which is not acceptable. So, current study focusses on friction stir welding of 6082 – T6 aluminum alloy.

Ключевые слова: Welding Technology, Friction Stir Welding, ANN, Aluminum Alloy

Похожие издания

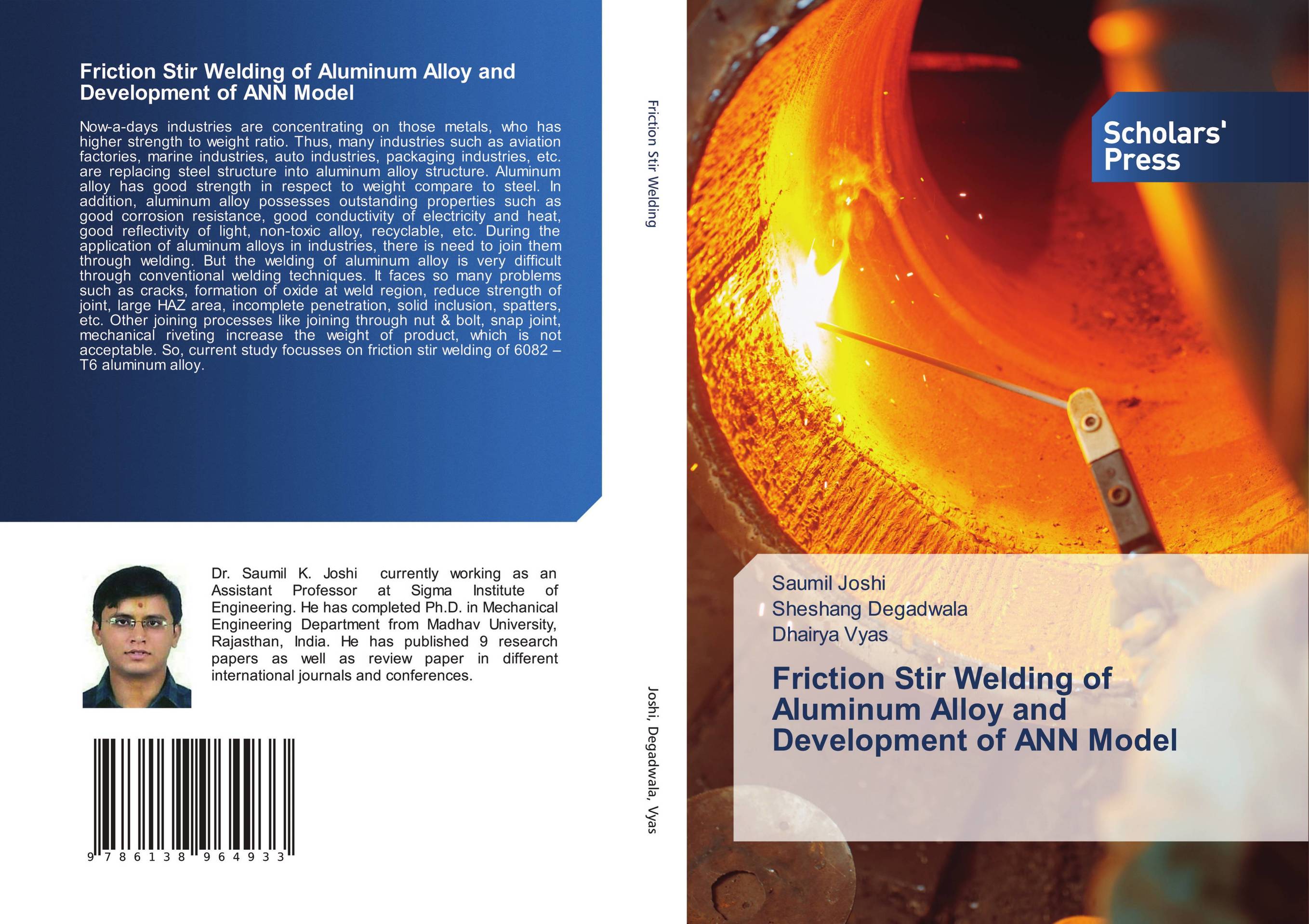

| Отрасли экономики: Машиностроение S Shashi Kumar and N Murugan An Insight to Friction Stir Welding of AISI 316L Stainless Steel. FSW Tool Materials; Process Parameters Optimization; Structure-Property relations; Pitting Corrosion; Underwater FSW. 1905 г., 232 стр., мягкий переплет The book gives insight to butt joining of AISI 316L stainless steel of 3 mm thick by FSW process (from first attempt to a successful weld).The preliminary experimental trials were carried out to identify a potential FSW tool material.Three tungsten based FSW tools were identified and a detailed experimental analysis was performed. The weld quality... | 53518 тг |

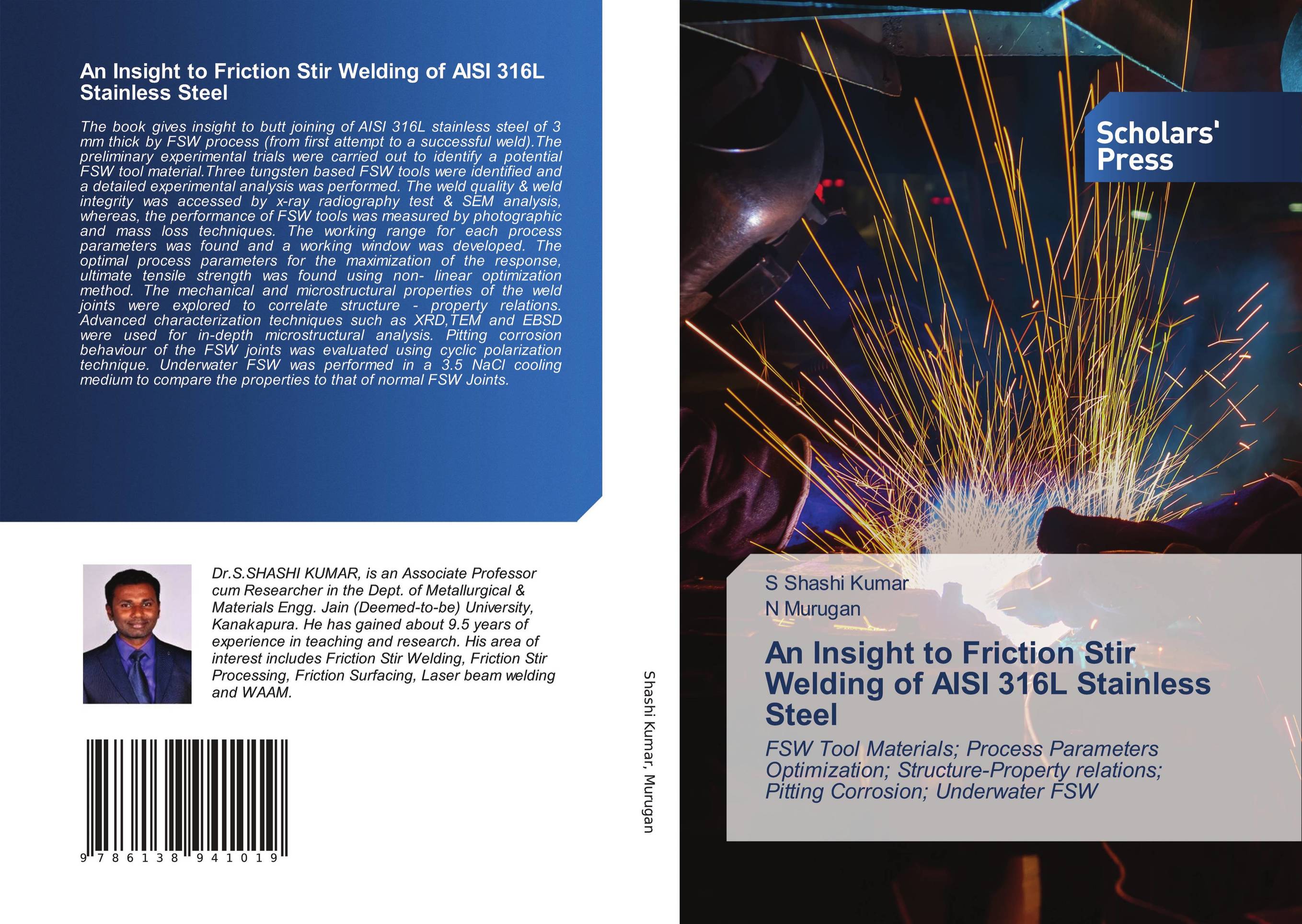

| Отрасли экономики: Машиностроение Dakarapu Santha Rao,M.P. Chakravarthy and MOHAMMED ABDUL SHAFEEQ Friction Stir Welding Of Dissimilar Aluminum Alloys.. 1905 г., 68 стр., мягкий переплет Friction stir welding (FSW) is a solid state welding process in which the relative motion between the tool and workpiece produces heat which makes the material of two edges joined plastic atomic diffusion. This method relies on direct conversion of mechanical energy to thermal energy to form the weld without the application of heat from... | 25429 тг |

| Отрасли экономики: Машиностроение Lingaraju Dumpala and Santosh Kumar Rambhukta Friction Stir Welding of AA6061. An Experimental Investigation on Mechanical Properties and its Microstructural Characteristics. 1905 г., 108 стр., мягкий переплет The main purpose of this research work is to analyse the prospective features of the Normal FSW of AA6061 butt, lap, and butt lap joints by analysing the mechanical properties and microstructural properties. In this present work, we perform the friction stir welding of AA6061 at various tool rotational speeds of 1100rpm and 1400rpm. These two FSW... | 35077 тг |

| Отрасли экономики: Машиностроение Adarsha Kumar Kaladari,Suryanarayana Murthy Battula and Ravindra ANDUKURI FRICTION STIR WELDING OF DISSIMILAR MATERIALS. (Effect of processing parameters on corrosion properties of Aluminium and Copper). 1905 г., 84 стр., мягкий переплет The primary objective of this book is to make it available to students, researchers, and those who are working on case study projects. Friction stir welding (FSW) is a newer solid-state joining technology. This joining technique is low-energy, eco-friendly, and versatile. It is especially useful for joining high-strength aerospace aluminium alloys... | 25997 тг |

| Отрасли экономики: Машиностроение Dr. Sadashiva M,Dr. H. K Shivanand and Mr. M Yunus Sheik Friction stir welding of aluminum 6061 hybrid metal matrix composite. Investigation of mechanical properties. 1905 г., 68 стр., мягкий переплет Cast aluminium 6061 alloy is most widely used in advanced engineering fields like marine engineering, automobile, aircraft, construction and R&D due to there unique properties like corrosion resistance, light weight, high specific strength how ever to extend there applications limits, there is a requirement for the reinforcement which will... | 23493 тг |

| Отрасли экономики: Машиностроение G. Elatharasan and R. Manikandan Some Studies on Friction Stir Welding of Dissimilar Alloys. Solid-State Welding Technique. 1905 г., 196 стр., мягкий переплет Friction Stir Welding (FSW) is a solid-state Welding Technique. The non-consumable tool, with a profiled probe and shoulder, is rotated and plunged into the interface between two work pieces. It then traverses along the joint line, causing the material to heat and soften. The shoulder also acts to contain this plasticized material, which is... | 43528 тг |

| Отрасли экономики: Машиностроение Santhiyagu Joseph Vijay and Natarajan Murugan Friction Stir Welding of Al-TiB2 Metal Matrix Composite. Investigations on Friction Stir Welding of Aluminum - Titanium Boride Metal Matrix Composite. 2020 г., 204 стр., мягкий переплет The book deals with explaining the stir casting procedure to fabricate metal matric composites, in specific a combination made of aluminum matrix and titanium boride particle reinforcement. The procedures for basic characterization of the composite is also explained in detail. The book also presents the procedures to join such difficult to weld... | 47683 тг |

| Отрасли экономики: Машиностроение Lingerew Enbakom and Mesay Alemu Optimization of Friction Stir Welding Process Parameters. Numerical, Experimental Analysis and Parametric Optimization of Friction Stir Welding on AA-6061 Aluminum Alloys. 2020 г., 92 стр., мягкий переплет Process parameters such as rotational speed, welding speed and tool profile were selected to show the effect of each parameter on tensile strength and hardness of joint. The physical observation, software analysis and experimental testing methods were considered to achieve the goal of this study. Finite element simulation was implemented in ABAQUS... | 31605 тг |

| Отрасли экономики: Машиностроение C. Chanakyan,M. Meignanamoorthy and K. Jagathesh Friction Stir Welding of Dissimilar Aluminium Alloys. Aerospace, Automotive and Marine Applications. 2020 г., 96 стр., мягкий переплет This book provides a practical understanding about the friction stir welding (FSW) of dissimilar alumiunium alloys. It considers about the effect of friction stir welding process parameters on the output responses tensile strength and hardness. Friction stir welding of aluminium alloys are playing a vital role in aerospace, automotive and marine... | 31747 тг |

| Отрасли знаний: Науки о Земле -> Геология и геофизика -> Теоретическая геология -> Минералогия Shubham Verma and Joy Prakash Misra Friction Stir Welding of AA6082. . 2019 г., 112 стр., мягкий переплет In present scenario, ferrous metals are increasingly replaced by non-ferrous metals especially aluminium alloys in case of structural applications owing to their unique features: high strength to weight ratio, high formability, excellent corrosion resistance, etc. Although, welding of aluminium is a major problem faced by aerospace, marine and... | 32315 тг |

| B Krishna Murthy and Satish Geeri Investigation of Weld by Friction Stir Welding of Various Tool Profile. . 2019 г., 68 стр., мягкий переплет Friction Stir Welding (FSW) is a relatively new solid-state joining process. This joining technique is energy efficient, environment friendly, and versatile. In FSW parameters play an important role like tool design, tool rotational speed, and axial force. To get effective welding joint need to concentrate on process parameters on FSW. Weld... | 26397 тг |

| Отрасли знаний: Точные науки -> Математика -> Анализ Ramatenki Naganand The Friction Stir Welding Tools Using different Composite Materials. . 2019 г., 100 стр., мягкий переплет Rotor disc intended for normal use in are commonly produced by gravity casting. If the cooling process and the initial temperature of the mold are not well controlled, shrinkage cavity will occur after solidification, causing leakage in the disc wheel. In this research, casting simulation software is used to simulate the casting process of rotor... | 31889 тг |

| Отрасли экономики: Машиностроение Harvinder Singh and Rajdeep Singh Friction Stir Welding and Processing. . 2018 г., 88 стр., мягкий переплет Friction stir welding (FSW) is a relatively new solid-state joining process. This joining technique is energy efficient, environment friendly, and versatile. In particular, it can be used to join high-strength aerospace aluminum alloys and other metallic alloys that are hard to weld by conventional fusion welding. FSW is considered to be the most... | 24203 тг |

| Отрасли экономики: Машиностроение Ashok Kumar Vootla Investigations & Analysis Of FSW Of Various Aluminium alloys. Experimental Investigations And Finite Element Analysis Of Friction Stir Welding Of Various Aluminium Alloys. 2018 г., 100 стр., мягкий переплет The book aims at providing the unique information on friction stir welding process. FSW is an outstanding-state method which produces welds of high best in complex-to-weld substances comparable to aluminum, and is quick becoming the approach of alternative for manufacturing lightweight transport structures similar to boats, trains and aero planes.... | 31889 тг |

| Отрасли экономики: Машиностроение Gadde Raghu Babu Friction Stir welding studies on aluminium Alloy. An Experimental Investigation. 2018 г., 112 стр., мягкий переплет The major contribution in this book is to study and investigate the effect of rotational speed, welding speed, axial force and tool pin profile on weld quality. Friction stir welds find use for structural and other fabrication industries. This book provides details of FSW equipment used and explains the effect of welding speed, rotational speed... | 26991 тг |

| Отрасли экономики: Машиностроение Mohammad Israr and Jignesh J. Patel Optimization of friction stir welding parameters for Aluminium Alloy. . 2018 г., 180 стр., мягкий переплет Friction stir welding is a recent promising solid state joining technique used to join high strength aluminium alloy. This present work focused to evaluate the effect of process parameters such as tool rotational speed; welding speed and shoulder diameter on yield strength and tensile strength of 6 mm thickness friction stir welded AA7075-0... | 46830 тг |

| Отрасли экономики: Машиностроение Md. Aleem Pasha Friction Stir Welding of Magnesium Alloy AZ31B. . 2018 г., 128 стр., мягкий переплет FSW is a joining process that employs a cylindrical shouldered tool with a probe (pin), rotates and plunges into the two consecutive parts of workpieces and furthermore traverses slowly along the joint line to produce weldment. The use of magnesium alloy as the structural material has been generally increasing in automobile, electronics and other... | 30464 тг |

| Отрасли экономики: Машиностроение Md. Aleem Pasha Reinforced and Unreinforced Friction stir welding of AA6061. . 2018 г., 132 стр., мягкий переплет This book presents the enhancement of mechanical properties of friction stir welded portion of Aluminium alloy 6061 by incorporating additional reinforcing particulates of silicon carbide and aluminium oxide at weld interface. Silicon carbide and aluminium oxide has been added as reinforcement by creating separate geometry, at the edges, where the... | 33510 тг |

| Отрасли экономики: Машиностроение Vinod Kumar,Neeraj Sharma and Aneesh Goyal Friction Stir Welding of Aluminum Alloys AA1100. . 2018 г., 88 стр., мягкий переплет Friction stir welding (FSW) is a relatively new solid state welding process which is used for butt joints. FSW was invented by The Welding Institute, Cambridge, UK in 1991 and has emerged as a new process for welding of aluminum alloys. This process has made possible to weld a number of aluminum alloys that were previously not recommended (2000... | 22267 тг |

| BIKRAM JIT SINGH and Rahul Singla DOE: A Boom for Multi-Response Optimization of FSW. -A Guide for Effective Friction Stir Welding of Dissimilar Aluminium Alloys. 2018 г., 120 стр., мягкий переплет Friction Stir Welding is a fairly recent technique that utilizes a non consumable rotating welding tool to generate frictional heat and plastic deformation at the welding location, affecting the formation of a joint while the material is in the solid state. The basic principle of FSW involves simultaneous application of pressure and relative... | 30180 тг |

| Отрасли экономики: Машиностроение Tanmoy Medhi,Barnik Saha Roy and Subhash Chandra Saha Thermomechanical Modelling Of Friction Stir Welding. Thermomechanical Modelling Of Friction Stir Welding Process And Study The Effect Of Process Parameters. 2017 г., 188 стр., мягкий переплет Friction stir welding is a solid state joining technique, where a non-consumable rotating tool with a specially designed pin and shoulder is plunged into the abutting edges of a sheet or plate and simultaneously traversed along the joint line. The physical understanding of the process is described by the combined effort of experimental examination... | 47115 тг |

| Отрасли экономики: Машиностроение Barnik Saha Roy 3D Modeling & Finite Element Analysis of Friction Stir Welding Process. Modeling of Temperature distribution and material flow in Friction Stir Welding of AA6061-T6. 2017 г., 164 стр., мягкий переплет A 3D thermal pseudo mechanical model formulated in an Eulerian frame considering a quassi-steady approach to Friction Stir welding modeling is proposed and implemented using nonlinear finite element code in Comsol Multiphysics . In this numerical model the aluminum is treated as a highly viscous, shear thinning liquid. A moving coordinate is... | 39002 тг |

| Отрасли экономики: Машиностроение P. Sevvel and V. Jaiganesh Friction Stir Welding of Dissimilar Mg Alloys. . 2017 г., 192 стр., мягкий переплет Friction Stir Welding (FSW), an innovative type of solid state welding technique invented & developed by The Welding Institute (TWI), can present higher potential for magnesium alloys. Because, it utilizes a non-consumable rotating tool to produce frictional heat and thereby creating plastic deformation at the location of welding. FSW is termed as... | 28865 тг |

| Отрасли экономики: Машиностроение Kanwal Jeet Singh and Mohit Sharma Friction Stir Welding of Aluminium. Experimental Investigation & Optimization of Process Parameters Involved In FSW of Aluminium by Doping of Pb and Zn. 2017 г., 84 стр., мягкий переплет Experimental investigations of Aluminium plates by doping of metals such as lead and zinc by solid state diffusion process before being joined by friction stir welded was carried out successfully. Same metal weld and work piece don’t give the better strength at the welding point. So the alternative is made the metal alloy at the point of weld.... | 22125 тг |

| Отрасли экономики: Машиностроение Sankaralingam Ravikumar and Venkat Pranesh Friction Stir Welding of Dissimilar Age-Hardenable Aluminium Alloys. An Experimental and Optimizational Investigation between AA6061-T651 and AA7075-T651. 2016 г., 216 стр., мягкий переплет This book analyse the mechanical properties with macro and micro structural characteristics of dissimilar friction stir welding between AA6061-T651 and AA7075T651 aluminium alloys. Most of the researchers analysed the dissimilar joints with various combinations and different temper conditions between heat treatable aluminium alloys. Hence this... | 43270 тг |

| Отрасли экономики: Машиностроение Mohd Anees Siddiqui Temperature Distribution in Friction Stir Welding of Aluminium Alloy. Modeling and Simulation of Friction Stir Welding Process by using HyperWorks. 2016 г., 112 стр., мягкий переплет As far as research in the area of friction stir welding is concerned, there are two types of model which are physical model and analytical model. Both the models have their own advantages and limitations and they are selected as per the availability and objectives of the research. Apart from physical model based on the experimental work, there is... | 32315 тг |

| Отрасли экономики: Машиностроение Mohamadreza Nourani,Abbas S. Milani and Spiro Yannacopoulos Friction Stir Welding of Aluminum Alloys. . 2014 г., 232 стр., мягкий переплет The main objective of this book is a novel integrated multiphysics modeling, testing, and optimization of friction stir welding (FSW) for aluminum alloys, and thereby facilitating a better understating of processing-microstructure-properties relationships in this relatively new welding technique. To this end, first we review various models and... | 53518 тг |

| Отрасли экономики: Машиностроение Muna Abbass and Hassan Abed Behavior of Different Welded joints in erosive - corrosive media. Friction stir welding TIG Welding. 2014 г., 128 стр., мягкий переплет Aluminum alloys (6XXX series) are widely used in the structural components of automotive and construction industries as they show a good combination of formability, corrosion resistance, weldability, and final mechanical properties. In this study two different welding processes have been considered: a conventional tungsten inert gas (TIG) and a... | 32883 тг |

| Отрасли экономики: Машиностроение Gurmeet Singh Cheema,Kulwant Singh and Jagtar Singh Friction Stir Welding of Aluminium Alloy. Some Investigations in Friction Stir Welding of Aluminium Alloy 6082. 2013 г., 140 стр., мягкий переплет In this research work an attempt has been made to develop an empirical relationship between FSW variables and the mechanical properties (tensile strength, yield strength, percentage elongation, micro hardness and impact toughness) of friction stir welded aluminium alloy 6082-T651 joints. Central composite design matrix was used to prescribe the... | 33794 тг |

| Отрасли экономики: Машиностроение Mayank Patel,Bhasker Shrivastava and Sharad Shrivastava Introduction of Friction Stir Welding. . 2013 г., 68 стр., мягкий переплет This comprehensive text focuses at providing conceptual understanding of various topics of Friction Stir Welding meant for all students of diploma Mechanical engineering and Fabrication Engineering.the book contain tool material, tool design, material flow, E-tool design, applications and machines for Friction Stir Welding. Salient Features: The... | 23493 тг |

| Отрасли экономики: Машиностроение Abdul Arif Numerical Analysis of Friction Stir Welding of Dissimilar Materials. Modeling for Temperature Distribution and Residual Stresses of AA5086 & AA6061 by using ANSYS. 2013 г., 88 стр., мягкий переплет Friction stir welding (FSW) is the latest technology in the area of metal joining and the most promising of all the welding processes. FSW technology produces welds that are stronger and more durable than other techniques, and it can be done faster, resulting in less cost. This technique has now become an important process in the joining of... | 24203 тг |